Design & Development

What Defines our Approach

Our diverse and experienced team has global exposure, with industry veterans from renowned companies and top institutes, dedicated to delivering exceptional results in following domains:

- Electrical

- Electronics

- Mechanical

- Magnetics

- Pneumatics

- Air Conditioning

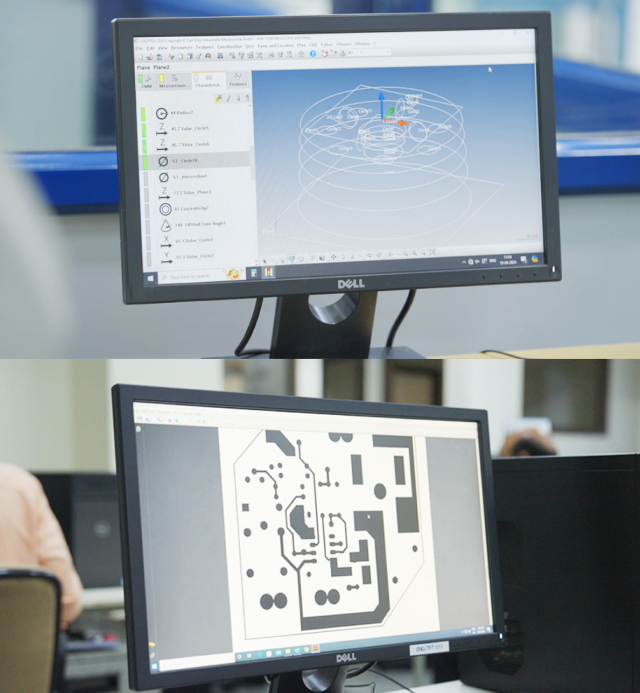

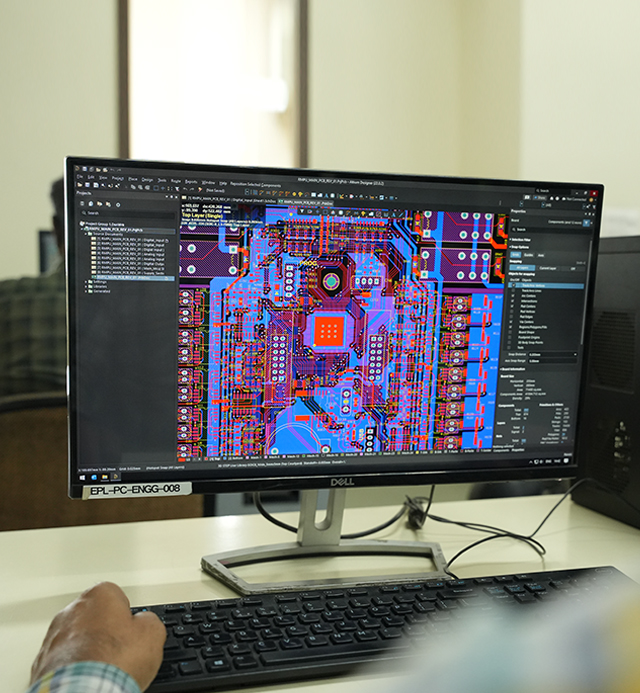

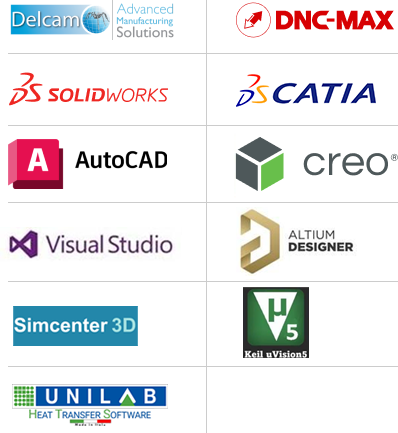

Our infrastructure is equipped with cutting-edge software and systems that enhance our design and manufacturing capabilities. Our tools include:

Quality Assurance

How We Ensure Excellence

Calibration Facility

Our calibration facility features reference equipment calibrated by National Accredited Test Labs, ensuring traceability to National and International standards for maximum accuracy and reliability.

Computerized Decision Support System

We use a fully computerized decision support and control system for managing incoming materials. Our in-house software enhances efficiency and accuracy, ensuring only high-quality materials are used.

Vendor Evaluation and Assessment

Continuous vendor evaluation and assessment maintain high standards throughout our supply chain, ensuring suppliers consistently meet our rigorous quality requirements.

Quality Audits and Pre-Dispatch Inspection

Regular quality audits and thorough pre-dispatch inspections ensure every product meets our stringent standards before leaving our facility, providing clients with reliable, high-performance products.

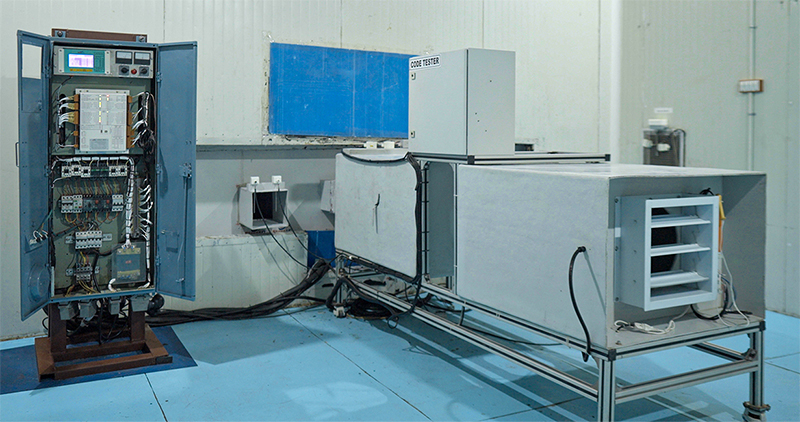

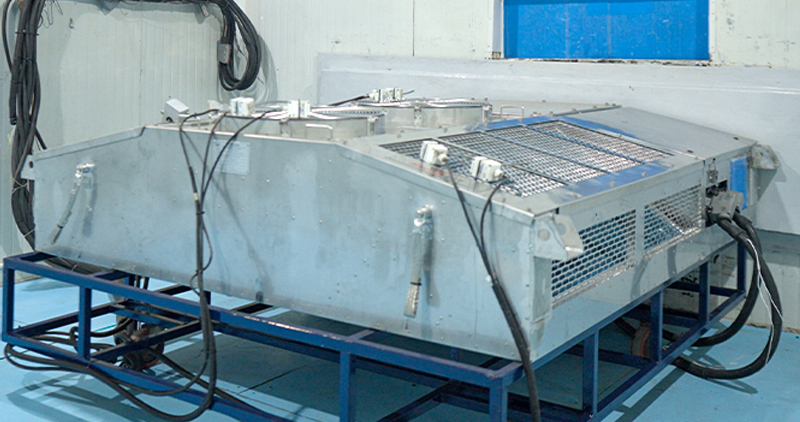

Manufacturing Facility

How We Excel in Production

01

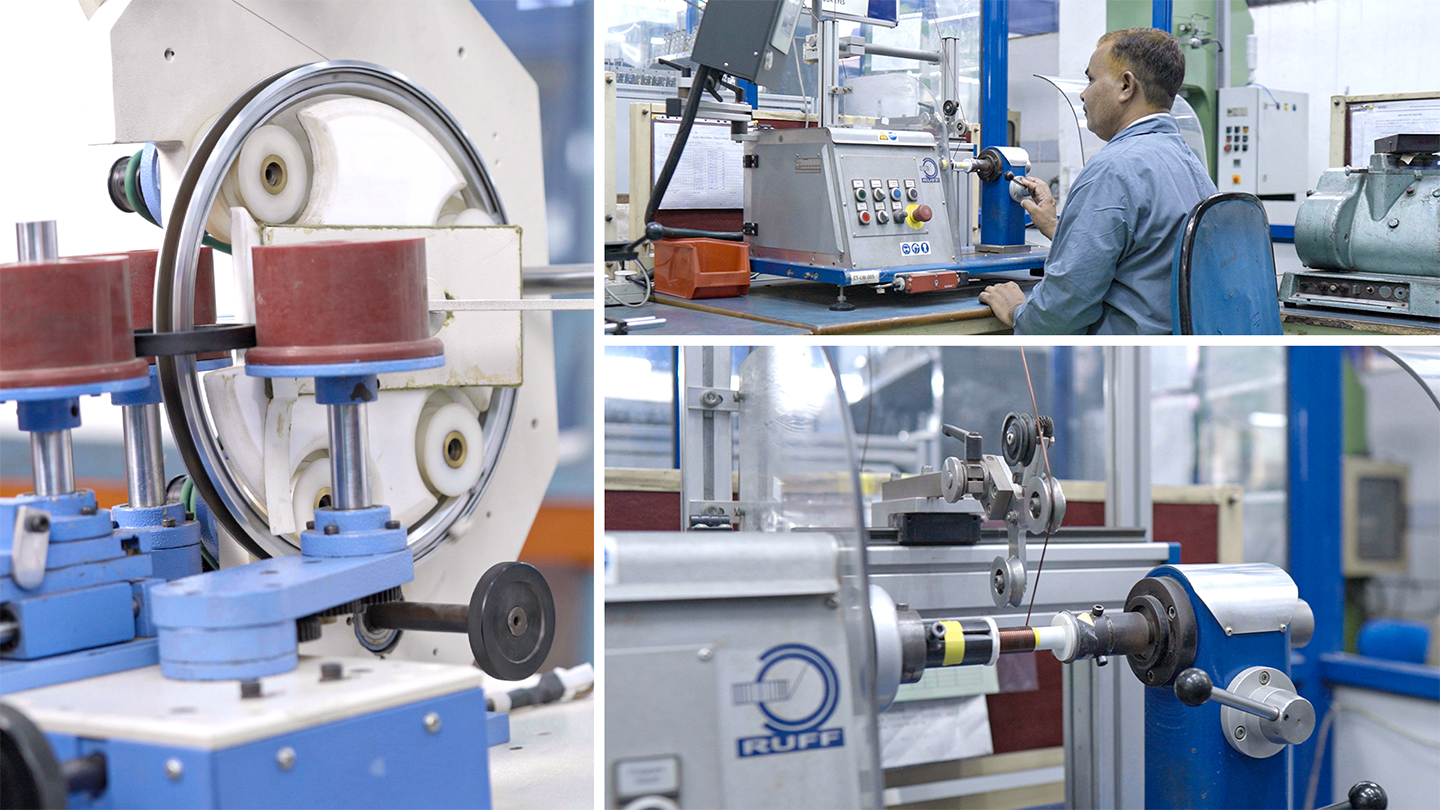

Advanced CNC and Mechanical Equipment

Versatile CNC machines and other specified mechanical equipment for milling, boring, drilling, contouring etc.

02

4-Axis Vertical Machining Centre

(X=425, Y=580, Z=510mm to X=1800, Y=800,

Z=1000mm) Travel Resolution: 0.001mm (1 Micron)

03

Electro-mechanical Assembly Set-up

Comprehensive Setup for Precision Assembly

04

CNC Turning Centre

Capacity: Ø0.5 to Ø450mm & Length: 0.1 to 600mm

Travel Resolution: 0.001mm (1 Micron)